Degele Manufacturing, Inc. is a family-owned, veteran-operated metal stamping and tool & die company based in Michigan, proudly serving the automotive and industrial sectors for over 50 years.

2,500 – Millions small parts annually, 500 – 100,000 complex assemblies annually

CAD – read most popular formats (Solidworks), Design for Manufacturability, Short-run production

Welding, Brazing, Tumbling, Fixtures, Wire EDM, CNC Milling and Turning, Outsource – waterjet, laser, heat treat and finishing

Welcome to Degele Manufacturing Inc.

Degele Manufacturing Inc. has been in business since 1970, you can count on DMI to meet or exceed your expectations on any program we start.

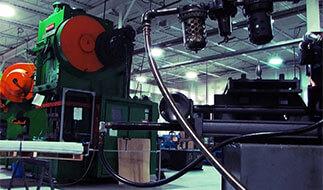

Our process oriented manufacturing capabilities saves time and money. Separate areas for tooling, machining, manufacturing, inspection, assembly and maintenance help make DMI one of the most efficient value added manufacturers in the industry. DMI features small to large scale stamping capabilities. Save the time and money of sourcing your stampings and assemblies from multiple sources Our stamping presses from 40 to 400 ton to meet most customer application needs.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Learn More AboutDegele Manufacturing

Join our community of satisfied industrial customers.

Sollicitudin mattis in cubilia scelerisque habitant morbi sociosqu si mi pulvinar. Mollis consequat fringilla nisl tristique ullamcorper.

Products & Services

Save the time and cost of dealing with multiple suppliers.

We take your project from design to prototype; build the tooling.

Discover More About Degele Manufacturing

How High-Precision Stamping Reinforces Metal Parts Manufacturing

When it comes to the manufacturing of metal parts, precision is not just a nicety- it is a necessity. At the heart of this process lies high-precision stamping, which is the cornerstone of manufacturing modern metal parts, and it can easily determine and assess the quality, the reliability, and the performance of the many different […]

Surprising Facts About Metal Stamping and Deep Draw Production

Have you ever thought about how the metal components of your car, appliances, or electronics are made? An interesting world of metal stamping and deep draw production-two manufacturing processes that are behind these daily items-has become a very important part of modern industry. These processes take flat metal sheets and, with amazing precision, convert them […]

Progressive Dies Explained: How Draw Dies Work and Their Applications

The majority of metal parts used in cars, electrical devices, and household appliances are derived from flat sheets of metal and then shaped into intricate designs through the use of progressive dies and metal stamping methods. One of the main features of progressive dies is that they are very efficient manufacturing tools that, along with […]

Trusted by 25,000+ world-class brands and organizations of all sizes.

What Our CustomersHave To Say

Posted onTrustindex verifies that the original source of the review is Google. This facility was able to produce very high quality, class A components for Tesla's vehicles. Very well kept shop with flexible possibilities for it's customers. Business owner is very accommodating, and respected by his customers and employees. Highly recommended.Posted onTrustindex verifies that the original source of the review is Google. Very good service and great product. I have used them multiple times over the years and definitely will again.Posted onTrustindex verifies that the original source of the review is Google. Degele Manufacturing has done a great deal of work for my company, Continental Industrial Services, and has always gone above and beyond with great customer service, always on time or early with production delivery and flawless quality. This is a great company to do business with.Posted onTrustindex verifies that the original source of the review is Google. I was very happy with the work from the whole Degele Manufacturing Team. My order was expedited quickly and with great quality control. Our company will certainly be using them again.Posted onTrustindex verifies that the original source of the review is Google. Family run company that cares about there customers and employees. Some employees have been there for over 40 years. Highly recommend!Posted onTrustindex verifies that the original source of the review is Google. Family owned business for over 40yrs! Strong values and work ethic!! Important customer satisfaction with meticulous quality control!Posted onTrustindex verifies that the original source of the review is Google. Have used on several occasions . They were on time and product was to print. easy to work with. we will use again.Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

FAQs

Can you provide lightweighting solutions for automotive or aerospace parts?

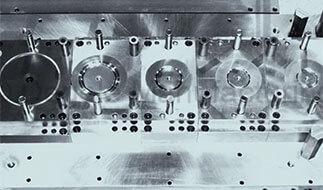

We at Degele Manufacturing, through our fully equipped in-house tool and die department, has the advantage of designing, building, maintaining, and repairing tooling without the need to depend on third-party vendors. This quality of capability has a great impact on lead times reduction, quality control improvement, and fast responses given to changes or maintenance requirements. In-house tooling means constant performance throughout the program’s life and, thus, greater reliability and flexibility for our customers.

Do you build and maintain tooling in-house?

Of course, we at Degele Manufacturing have a tool and die department with the necessary equipment in-house, resulting in us being able to design, build, maintain, and repair tooling as required without depending on third-party vendors. This feature basically makes it possible to shorten the period of time from order to delivery, improve quality checks, and allow quick reactions when changes or maintenance come up. Having tooling done in-house guarantees that the quality would be the same for the entire program duration and it would also create more dependable and flexible conditions for our customers.

What is your minimum quantity requirement (MOQ) for domestic vs. offshore orders?

Due to stamping needing a custom tooling pre-payment, Degele Manufacturing usually experiences the best worth of domestic production at moderate to high volumes- frequently beginning from hundreds to thousands of pieces according to part complexity. Instead of the offshore sourcing, our domestic sourcing has the advantages of less MOQs, faster turnaround, easy engineering changes and less logistics risk. If the volume is lower we can suggest some other processes like machining or fabrication so stamping is not the most cost-effective solution.

How are you mitigating the impact of current steel and material tariffs?

We have managed to mitigate the effects of tariffs on materials through a combination of sourcing from several suppliers, establishing good relationships with domestic suppliers, and an active material planning strategy.

Can you handle high-precision stamping for miniaturized electronics?

Yes. Degele Manufacturing has been dealing with the high-precision stamping of small, intricate components for electronics and other tiny applications for a long time. Thin materials are usually processed by us, and we are able to maintain tight tolerances through progressive dies, precision presses, and advanced inspection equipment. Our process control, tooling expertise, and quality systems enable us to manufacture complex, small-form components with great consistency according to strict dimensional and performance specifications.